Miscellaneous Questions #4

This section continues the discussions of various

ballistics and shooting related topics as requested by correspondents. If you have a

question you have been trying to find an answer to (keep 'em ballistics or shooting

related--see your minister for the mysteries of life) email me by clicking

here and I'll do my best to find the

answer for you and if it is of general interest, publish it here. If you can contribute

additional input to one of the answers I'd would appreciate hearing from you too.

This is a fairly long page and may be slow to

load. MS Front Page says 54 seconds at 28.8.

On this page:

Are oils and solvents dangerous to

ammunition?

How much power do I really need in a telescopic sight?

What is the best reticle to use?

What are some good general tests of someone's shooting skills?

At what range should I zero my (supply your own caliber)

rifle?

How do changing various components affect chamber pressure

and velocity?

Are the 7.62 x 51 mm NATO rounds and the .308

Winchester really the same round?

Are the 5.56 mm NATO rounds (and M193 types) and the .223

Remington really the same round?

What was the largest gun in history?

Can you recommend any "homemade" gun

cleaning solutions?

Q. Are oils and solvents

dangerous to ammunition?

A. Absolutely! One of the

characteristics of gun oils and cleaning solvents is their great penetrating capability.

This allows them to seep into places that one wouldn't expect. This can lead to the

deactivating of primers and powder which will result in an embarrassing click (or maybe a

"Pfffftt!") when you expect a bang. In one test, ammunition was deactivated or

substantially degraded in performance in as little as 4 hours after being sprayed lightly

with a well known lubricants.

In addition, any lubrication on a cartridge case can cause excessive back

pressure on the bolt because the case will be unable to grip the chamber walls, not to

mention the attraction of dirt..

Keep ammunition well away from any solvents and lubricants and

ensure that

your ammunition and chamber are dry prior to firing, and remember--when

lubricating your firearm use the minimum amount of lube possible. You want

it lubricated and not an oil field.

Q. How much power do I really need in a telescopic sight?

A. Before we can

discuss this topic we have to first understand that a telescopic sight doesn't make for a

more accurate firearm. Nor does higher magnification lead to greater accuracy. A

telescopic sight simply allows the user to more easily pick out a target from the

background. In addition, while higher magnification can reveal greater detail it also

magnifies vibration and can actually make a target harder to hit because the shooter

subconsciously tries to "beat" the motion.

For general field use somewhere between 2x and 4x is

probably the most useful with 6x possibly of use for extended ranges. Beyond these,

holding under field conditions becomes difficult and visible mirage can cause

additional problems. Keep in mind that 95 percent of all

shots in the field are under 200 yards with the majority of them under 100 yards (despite

what the gunshop cowboys may claim). With a scope of too high a power it can actually

become difficult to hit close in targets, especially quickly, because of their highly

magnified image.

A variable power scope can provide the best of

both worlds, but keep in mind that the field of view for variables is less than

for fixed power scopes, and while modern variable power scopes are

very reliable they can exhibit a change of point of impact when changing magnification. If

you choose this kind of sight verify that the point of impact remains the same when

changing settings.

Some folks recommend variable power scopes

because they claim can scan for a target with the higher magnification and then switch to a lower

setting for the shot (or some say the other way around). However, doing this violate a

primary rule of firearms safety--Never point your firearm at anything you don't intend to

shoot. Binoculars should be used for searching.

Q. What is the best reticle

to use?

A. The choice of

reticle to use is one of those things "you gotta try yourself" as personal

preferences vary greatly. My preference is for what is known as a "duplex"

reticle which tends to lead the eye to the center because of its thicker outer legs yet

which offers a fine aim point when needed. See the illustrations below of some common

reticles and comments about them and the draw your own conclusions. If I could design my

own reticle it would be similar to the heavy duplex for the outside legs but the inner

wires would be as fine as the standard duplex as shown I have shown.

|

|

|

|

|

|

|

| Standard

Crosshair |

Duplex

Crosshair |

Heavy

Duplex |

MilDot |

| Gives precision

aim point but is hard to see in dim light or to pick up quickly |

Gives precision

aim point and aim point can be seen in dim light. Faster aim point pick up then standard. |

Aim point is not

as precise for target use but extremely fast to use under field conditions. |

Used

for ranging purposes and growing in popularity |

|

|

|

|

|

| German #4 |

German #1 |

Post & Duplex |

| A European reticle

that provides fast acquisition with a fine aim point |

A European reticle

that provides fast acquisition. Popular in the military. |

Similar to the German #4

but offering a more open view |

|

| Fr. Frog #1 |

| This would give very fast

pickup under all conditions yet provide for a precise aim point when needed. This design

would probably require an etched glass reticle as current wire technology may not permit

this design. A "post & duplex" version would also be acceptable. Asked to

provide dimensions I'd say a thick section of about 3 or 4 moa and a thin section of .7 moa.

For the spacing between the ends of the thick sections between 18 and 24 moa tip to tip would

probably be

good. |

Leupold & Stevens has a wide variety of reticles that they will install in their

scope for a charge of about $47 and Premiere Reticles has an even larger selection for

Leupold scopes. Leupold's web site is at: http://www.leupold.com

and Premiere Reticles web site is at http://www.premierreticles.com.

Q. What are some good general tests of

someone's shooting skills?

A. There are a lot of folks out there who claim

to be incredible shots. So how can you find out the truth? First, we need to establish

that in the context of my web site we are talking about the practical

use of firearm and not gun games. Second, it's not what someone did once, but

what they can consistently do on demand time after time that counts. With

these things in mind there are several fairly easy to set up tests that will show whether

or not the claimer is as good as they claim to be.

Anyone who does consistently well at any of them is probably a pretty good shot with

their firearm. And remember, it's not what you did once but rather what you can do on

demand that counts. Click here for information on these courses

of fire.

Q. At what range should I zero my (supply your

own caliber) rifle?

A. Most folks zero their rifles at too close a

range. While most shots in the field are taken at fairly short range, zeroing too closely

limits (or at least makes more difficult) hitting targets of opportunity at longer ranges.

Ideally you want to zero your rifle at the longest range that the bullets path does not rise above half of

your target's vital zone. That way you can hold dead on out to a much longer distance than

if you simply zero for say, 100 yards.

If we assume, as many people do, a vital zone size of 6 inches, we want a zero such

that the bullet's path does not rise more than 3" above the line of sight. A good

general rule of thumb is to zero cartridges with a velocity of 2100 to 2300 f/s at about

180 yards, those with a velocity of 2400 - 2900 f/s at 225 yards, and those with a

velocity of 3000 f/s and over at 250 yards.

To obtain an good approximation of these zeros, adjust your point of impact to be

between 2.75 and 3 inches high at 100 yards (the lower figure for the lower velocities and

the higher figure for the higher velocities) and you will be in the ball park. With the

proper zero you will be able to hold dead center for ranges from up close to about 40

yards past your zero range (where the bullet drops more than 3 inches). You should, of

course, confirm things by actually firing at different ranges. (By the way, the .22 rim

fire because of its smaller normal targets is probably best set for about an 80 yard zero

which puts the bullet ¾ inches high at 25 yards, 1.5 inches high at 50 yards, and about

2.5 low at 100 yards.) Of course it goes without saying that you should verify you zero at

the actual ranges.

If you have ballistics software you can refine these calculations for your particular

load.

If you are interested in a more in depth discussion of zeroing visit the

"Zeroing" link on my

"ballistics" pages by clicking here.

Q. How do changing various components

affect chamber pressure and velocity?

A. Changing components can definitely affect

things as the tables below show for the .308 Winchester cartridge. As you can see from the

data, a change of almost 8,000 cup or more is possible simply by changing one component.

If multiple changes occurred the effect could be even greater, and if the initial load was

at or near maximum one could easily get into dangerous territory. This is especially true

of small capacity cases in high intensity rounds like the 9 x 19 mm where case capacity

can vary greatly. Note: These results were typical under the conditions tested. Your

firearm and ammunition may behave differently so don't use this as loading data.

| Changing Bullet

Brands |

Bullet Wt

(gr) |

Bullet Type |

Case |

Primer |

Powder |

Charge

(gr) |

Vel

(f/s) |

Pressure

(cup) |

| 168 |

Sierra |

LC |

W120 |

IMR-4895 |

40.5 gr |

2626 |

52.2k |

| " |

Speer |

" |

" |

" |

" |

2625 |

51.2k |

| " |

Hornady |

" |

" |

" |

" |

2625 |

51.2k |

| " |

Nosler |

" |

" |

" |

" |

2624 |

52.1k |

| Changing Primer

Brands |

Bullet Wt

(gr) |

Bullet Type |

Case |

Primer |

Powder |

Charge

(gr) |

Vel

(f/s) |

Pressure

(cup) |

| 168 |

Sierra |

LC |

W120 |

IMR-4895 |

40.5 |

2626 |

52.2k |

| " |

" |

" |

F210M |

" |

" |

2622 |

51.0k |

| " |

" |

" |

R9½ |

" |

" |

2571 |

45.5k |

| " |

" |

" |

CCI200 |

" |

" |

2581 |

45.5k |

| " |

" |

" |

CCI250 |

" |

" |

2579 |

46.1k |

| Changing Cases |

Bullet Wt

(gr) |

Bullet Type |

Case |

Primer |

Powder |

Charge

(gr) |

Vel

(f/s) |

Pressure

(cup) |

| 168 |

Sierra |

LC |

W120 |

IMR-4895 |

40.5 |

2626 |

52.2k |

| " |

" |

FC |

" |

" |

" |

2586 |

44.7k |

| " |

" |

WW |

" |

" |

" |

2580 |

45.3k |

| " |

" |

RP |

" |

" |

" |

2589 |

46.4k |

Data courtesy NRA.

Most reloaders standardize on a particular brand primer and bullet for a given load and

the factor most likely to change is the cartridge case since most shooters will pick up

anything that looks like brass. To give you an idea of how things can vary look at the

difference in case weights for representative cartridge cases that I have

measured. The weights are based upon the average of 10 fired,

cleaned, and unprimed

(but otherwise unmodified) cases. Your cases may differ with different

lots so don't count on these figures.

(If you can supply data on other cases I'd greatly appreciate it

| 9 mm Case Comparison |

| Brand |

Case Wt.

(gr) |

| Jegemann |

54.2 |

| S&W |

54.8 |

| Super Vel |

55.1 |

| Speer |

55.2 |

| WW |

55.3 |

| Starline |

57.3 |

| Remington |

58.1 |

| Browning |

58.9 |

| Hornady |

60.0 |

| Norma |

62.0 |

| Federal |

63.0 |

| Aguila |

63.0 |

Israeli Military

(TZ) |

66.2 |

US Specification for the

9 x 19 NATO cases is

"nominally 57 gr" |

|

|

.40 S&W

Case Comparison |

| Brand |

Case Wt.

(gr) |

| Federal Nickel |

63.4 |

| Federal |

63.6 |

| WW |

64.8 |

| Remington Nickel |

66.8 |

| GFL |

66.9 |

| Speer Nickel |

67.1 |

| CCI |

68.3 |

| |

|

| |

|

| |

|

|

| .308 Case Comparison |

| Brand |

Case Wt.

(gr) |

| Federal (old) |

158.2 |

| WW (Old) |

159.9 |

| Hirtenberger '84 |

161.3* |

| Norma |

165.6 |

| Remington |

170.5 |

| Lapua |

171.8 |

| Sako |

172.0 |

| Lapua(recent) |

173.2 |

| Federal (Current) |

175.4 |

| Federal Nickel (Current) |

177.1 |

| WCC 67 |

177.4 |

| LC 76 |

179.0 |

| Samson Match |

179.2 |

| WW (Current) |

179.2 |

| LC 77 |

179.3 |

| LC 79 MATCH |

179.4 |

| LC 67 MATCH |

179.5 |

| LC 74 |

179.9 |

| IMI 308 Win |

181.0 |

| FA 65 |

182.7 |

| FNM '82 |

194.1 |

| * These

case have a much smaller than normal flash hole

US Specification for the

7.62 x 51 NATO case is

190 +0, -20 gr

|

|

| 5.56

mm Case Comparison |

| Brand |

Case Wt.

(gr) |

| Federal |

88.6 |

| PMC |

91.3 |

| ZV 9 9 NATO |

91.4 |

| L C 9 2 NATO |

91.7 |

| L C 8 9 NATO |

92.5 |

| T W 6 8 |

92.5 |

| W C C 8 5 |

92.7 |

| WW Nickel |

92.8 |

| WW |

92.9 |

| IMI |

93.0 |

| WCC87 |

93.2 |

| Hornady |

no data |

| Norma |

no data |

| Remington |

no data |

| |

|

| |

|

| |

|

US Specification for the

5.56 mm cases are 94 -5 gr for M193 cases and 95 -6 gr

for M855 NATO cases |

|

|

.45 ACP Case

Comparison |

| Brand |

Case

Wt

(gr) |

| Federal |

84.2 |

| Winchester |

87.5 |

| R-P |

85.6 |

| IMT |

87.1 |

| WCC 67 |

|

US Specification for the

.45 ACP cases is "nominally 87 gr " |

|

.30

Carbine

Case Comparison |

| Brand |

Case Wt.

(gr) |

| WW |

71.6 |

| RP |

68.7 |

| RP-UMC |

71.4 |

| CBC |

73.0 |

| Federal |

69.9 |

| LC |

69.9 |

| S&B |

71.9 |

| WRA |

69.4 |

| WCCl |

69.5 |

| Aguila |

69.5 |

| |

|

| |

|

US Specification for the

.30 Carbine cases is 71 -6 gr |

|

In the 9 mm cases the difference in case weights translate to tremendous difference in

case capacity. There is an old rule of thumb that for equivalent pressure, charge weight

varies by about 12 percent of the difference in case weight. While this rule of

thumb is based upon .308/.30-06 size cases it hold true fairly closely for

other case sizes and can at least keep you out of major trouble.

For example, a load developed in 9 mm Winchester brass listed above would have to be reduced by about 1 gr in Remington cases

and a whopping 1.3 gr to maintain the same pressure in TZ cases. In a cartridge like the 9

mm where typical powder charges run 5 to 6 grains that's a big 22 percent change.

In the

.308 examples above the change incurred from the lightest to heaviest cases would be about

4 grains. With a typical 45 grain charge weight that's about an 8 percent change. It should

be noted that average case weight can vary from lot to lot (usually no more than about 2

gr) within a particular brand of rifle cases. With .308 size cases

differences in average weights of about 1.5 gr can probably be ignored

safely. In 5.56 the charge difference can be around .6 gr which with

an average charge of powder (27 gr) would about a 2 percent change. The .40

S&W has similar issues.

You should also be aware of the fact that the burning rate of your powder can change

slightly from lot to lot. Although the lot to lot consistency these days is quite

remarkable there is still the chance that things can change. (This is one reason why

big-time match shooters buy large quantities of a single lot of powder).

No wonder the reloading manuals caution you to drop at least 10 percent from any

maximum charge data and slowly work up. A good rule of thumb for the amount of

an increment to use when working up from a starting load is to fill the case to

the base of the neck with the powder you are using, dump and weight the powder, and to then

use 1 percent of that weight as an increment. As an example, if your case would

hold 55 grains of the powder you are using a good "increment" would be

.5 (5/10) of a grain. Once you get "in the ball park" for accuracy (see

the article on load development) you could then cut that increment to about half (say to .2 gr in this case) to fine

tune things.

Remember. Play it safe. If you change anything drop your load 10 percent and slowly

work back up.

A special warning! Seating

depth, especially in small capacity high pressure cases, like the 9 mm and .40 S&W, has a

major effect on pressure. Tests have shown a 20 - 25 percent change in pressures

with as little as .05" in seating depth in these cartridges. A chart

for the .40 S&W changing seating depth with the same charge and brand of

cases is shown below. If you couple a change from a thin case to a thicker

case with less volume and a change in seating depth it become clear that you can

get in big trouble very fast. This is especially true if you are using

cases that have been reloaded a lot and a pistol that has poor case head

support.

Change in

seating depth

(inches) |

Pressure

(psi) |

| 0 |

35,000 |

| -.05 |

41,500 |

| -.1 |

48,900 |

|

SAAMI specification for

the .40 S&W are

Max Average

Pressure - 35,000 psi

Maximum Probable Lot Mean - 36,100 psi

Maximum Sample Mean - 37,800 psi

Minimum Proof - 45,

5000 psi

Maximum Proof - 49,000 psi |

Pressure changes interpolated from data supplied

by Ramshot Powders.

Q. Are the 7.62 x 51 mm NATO rounds and the .308 Winchester

really the same round?

A. Well, er, ah, umm--kinda. The cartridge cases

themselves are effectively identical with the exception that the NATO specification

rounds (those marked with the NATO "cross in circle" mark) have substantially

thicker cases than the commercial variety and slightly different tolerances on

some dimensions . They are thus able to withstand stretching better when fired in loose

chambered military weapons (done for reliability purposes). There is

a pressure specification difference though.

| Cartridge |

Max Avg

(KPSI piezo) |

Nominal Proof

(KPSI piezo) |

Port Pressure

(KPsi piezo) |

| SAAMI |

62.0 |

83.0 - 89.0 |

n/a |

| NATO |

50.0 |

64.5 - 69.5 |

12.5 +/- 2 |

Thus commercial ammunition may over stress military firearms and their gas

systems and coupled with

the thinner commercial brass and the larger GI chamber may result in case

rupture.

The NATO specs for the cartridge case dimensions reference different datum points for

some measurements but these can be interpolated. Base diameter specifications

.2" from the base of the rim are approximately .4706" - .006" for

NATO specifications and .4703" -.008" for SAAMI. The

specifications for the diameter at the shoulder of the case is difficult to

compute as it is at the intersection of two datum lines but would probably be

slightly larger (.4543" -.006 by my interpolation) than the SAAMI specification of

.4540" +/- 0 at 1.450" from the base of the case. SAAMI gives the case

to shoulder length from the base to

the .400" datum on the shoulder as 1.627" - 1.634" while the NATO

spec is 1.628" - 1.634". However, I have gauged many military

rounds as being well under the minimum specification, especially non-US military

surplus. (After all it was surplused for a reason.)

The GI .7.62 mm chamber has a larger diameter neck (.3445" +.020 vs.

.3442" +.020 SAAMI), a different shaped and dimensioned bullet seat and

throat, and more generous diameter tolerances,

(.4730 + .002 (interpolated at the .200 reference line) compared to .4714 + .002

for SAAMI. I

am working on obtaining drawings for both the cartridges and the chambers and will post them when

available which will show the differences more clearly.

The headspacing requirements for the NATO chamber is much more generous than that of

the SAAMI commercial (.308 Winchester) specifications as can be seen in the table below.

(All dimensions are from the breech face to the .400" datum point at the

shoulder and are taken from SAAMI or US government specification sheets.)

| Gauge |

.308 Win |

7.62 MM NATO * |

7.62 MATCH * |

| GO (Minimum Chamber) |

1.630 +.002 |

1.6355 +.0005 |

1.6355

+.002 |

| NO-GO (Max Chamber) |

1.634 |

1.6405 +.0005 |

1.6385 |

| Field (Reject) |

1.638 |

1.6455 |

|

| * Using

"component" bolt |

Additional problems can arise when commercial .308 ammunition is fired in military specification

chambers since the minimum military chamber is .0015" longer than the SAAMI

maximum chamber. Since commercial ammunition is generally dimensioned to fit in a minimum

sized SAAMI chamber, the thinner commercial brass can be stretched to the failure point when

fired in maximum sized military chambers, while minimum spec military brass is

thick enough to stand the stretching.. In addition, military chambers may also be cut

on the "generous" size diameter-wise to allow for functioning with dirty

chambers. In the other direction, some military ammo may fail to chamber properly in very tight

commercial chambers, although it appears that military ammunition is generally

on the minimum side of specifications.

While reports of catastrophic failures seem to be almost unheard of, it is prudent to keep in mind

that there IS a difference and to use commercial .308 ammunition only in firearms marked

as .308 Winchester. Military ammunition that fits SAAMI chambers properly is

considered safe to use in non-military arms. The headspacing "problem" with military chambers can be

taken care of for a particular rifle and reloads by careful adjustment of your sizing die. Most "commercial" rechamberings are done with SAAMI spec chambers. If in doubt

or really paranoid do a chamber cast.

... and the .30-06. For all intents and purposes the cartridges

and chambers are the same. However, US military ammunition is loaded to a

specification of 50 - 54 Kpsi average (depending on the particular type of

round) while the current commercial .30-06 ammunition is loaded to 62 Kpsi

average. In bolt action rifles this isn't a major thing but in the M1

Garand use of commercial ammunition can lead to battering and the bending of the

operating rod.

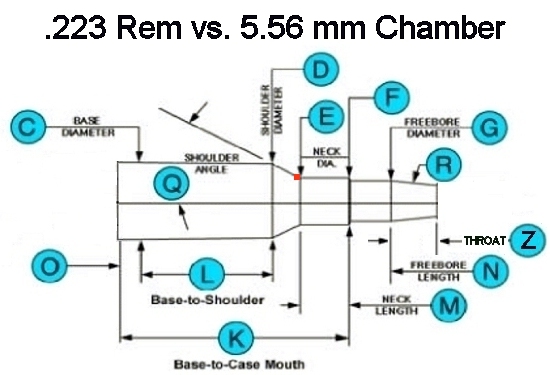

Q. Are the 5.56 mm NATO rounds (and

M193 types) and the .223 Remington really the same round?

A. This is another of those "Well, er, ah,

umm--kinda" items.

There is a slight difference between .223 Remington and 5.56 x 45 mm military

ammunition. While the cartridge cases themselves are identical

(although some dimensions are referenced to different datum points), with

the exception that military and/or NATO specification rounds (those marked with the NATO

"cross in circle" mark) may have thicker cases and are thus able to withstand

stretching better when fired in loose chambered military weapons (done for reliability

purposes). From the data I have seen the headspace

specifications are identical for SAAMI and military ammunition although,

again, measured

to different datum points and the dimensions of the cartridge cases are the

same. While the standard .223 and 5.56 NATO use

the same headspace gauges, the Colt factory uses a special "maximum field

gauge" that is much longer than the normal field gage to reject rifles.

| Gauge |

.223 & 5.56 NATO |

| GO (Minimum Chamber) |

1.4636 |

| NO-GO (Max Chamber) |

1.4666 |

| Field (Reject) |

1.4696 |

| Colt Factory GI Reject |

1.4736 |

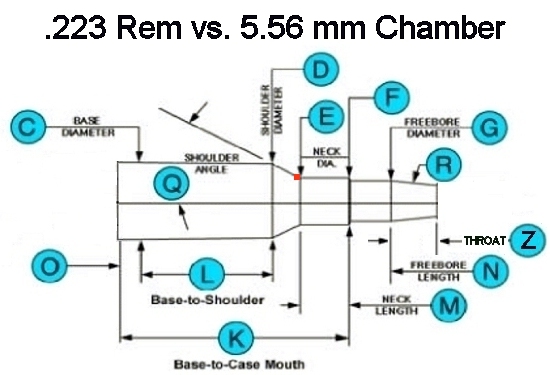

The chamber dimensions are where big differences are. While there are

just minor dimensional and tolerance differences in the body area, the big

differences are in the throat areas.

There are actually 3 standard chambers, SAAMI, US GI NATO, and FN NATO.

Commercial SAAMI specification .223 chambers have a much shorter throat, a smaller

diameter bullet seat, and less freebore than the US GI military

chamber and the NATO chambers. This

typically results in the ogive of the M193 Ball bullet touching the ball seat of

the SAAMI chamber. The profile of the M855 bullet is similar and it is also

loaded hotter than M193.. When military

specification ammunition is fired in a SAAMI specification chamber chamber pressure can

increase dramatically--M193 typically goes up 3 - 5K psi (from a nominal 55K,

while M855 goes up about 10K from a nominal 58K). While this should not cause any

problems in modern well made rifles it should give one pause. Conversely, SAAMI

specification commercial ammunition when fired in a military chamber gives significantly

lower pressures and velocities.

The reason the big difference in

the NATO chamber is that the deeper intrusion of the M856 tracer bullet into the

powder space was found under some conditions to cause riveting of the bullet,

which gave a steep pressure spike. (This has also been seen with 77 gr and 80 gr

match bullets.) Thus the FN NATO 5.56mm chamber has an intermediate

11 degree, 30 minute cone transitioning between the case shoulder and the case

neck to help eliminate this problem. as marked with the red dot on the drawing

below. This chamber is primarily used on the M249 SAW. The US

"NATO" chamber used in the

M16 rifles does not have this double shoulder but otherwise they are identical.

The data below shows the dimensional differences between the US

GI NATO and SAAMI chambers.

| Legend |

Item |

.223

SAAMI |

5.56

mm |

Difference |

| C |

Base Diameter |

.3803 |

.3803 |

0 |

| D |

Shoulder Diameter |

.3553 |

.3553 |

0 |

| E |

Neck |

.2550 |

.2551 |

.0001 |

| F |

Neck (Case mouth) |

.2540 |

.2540 |

.0 |

| G |

Freebore Diameter |

.2240 |

.2265 |

.0025 |

| K |

Base to Case Mouth |

1.7720 |

1.7750 |

.0030 |

| L |

Base to Shoulder |

1.4338 |

1.4338 |

0 |

| M |

Neck Length |

.2201 |

.2202 |

.0001 |

| N |

Freebore (Lead)

Length |

.0250 |

.0566 |

.0316 |

| O |

Datum Point From

Breach face |

.2000 |

.2000 |

0 |

| Q |

Shoulder Angle

(Deg) |

23 |

23 |

0 |

| R |

Throat Angle (Deg) |

3.10.36 |

1.13.25 |

-

1.57.06 |

| Z |

Throat Length |

.0811 |

.2693 |

.1182 |

|

Dimensions in inches.

SAAMI length tolerance = +.0050. NATO length tolerance =

+.0040. Diameter tolerance for both is +.0005 Angle tolerance

is SAAMI +/- 2 min, NATO is +/- 15 min

FN NATO CHAMBER - The above drawing does not

show the double shoulder angle (a the red dot) of the NATO chamber. The deeper intrusion of the M856 tracer bullet into the

powder space was found under some conditions to cause riveting of the bullet,

which gave a steep pressure spike. The FN NATO 5.56mm chamber has an intermediate

11 degree, 30 minute cone transitioning between the case shoulder and the case

neck (at the area marked by the red dot) to help eliminate this problem. The shallower NATO throat angle

gives a longer throat to the same dimension datum (.215 )than the SAAMI

spec. See drawing below for detail of the dual angle NATO chamber.

SAAMI data from SAAMI drawings

in ANSI/SAAMI Z299.4-1992.

US NATO data from print 8448549/8448550

|

|

|

*NATO dual angle detail |

It must also be noted that all 5.56 x 45 mm NATO ammunition (such as US

M855) requires a 1:9" twist or faster rifling to stabilize the long 62 gr ball bullet

and a 1:7" twist to stabilize the extremely long tracer variation. The standard

twist used for .223 Remington commercial chamberings is 1:12" or 1:14" neither

of which will stabilize the NATO type ammunition. There does seem to be a

recent push to standardize the 1:9 twist for .223 though. The NATO ball ammunition is easily

identified by its green bullet tip.

The piezo pressure specifications for SAAMI, M193, M855, and CIP (European

standards) ammunition are given

below. Keep in mind that the SAAMI pressures are taken in a SAAMI spec

test barrel and measured 32 mm from the base of the case. Military pressures are taken in a mil-spec

barrel and chamber and are measured at the case mouth. CIP pressures are

measured in a CIP standard chamber and are taken 25 mm from the case base.

| Standard |

Max Avg

(KPSI piezo) |

Individual Max

(KPSI piezo) |

Nominal Proof

(KPSI piezo) |

| SAAMI |

55.0 |

56.4 |

71.5 - 77 |

| M193 |

55.0 |

61.0 |

70.0 +/- 3.5K |

| M855/NATO |

58.7 |

64.7 |

70.0 +/- 3.5K |

| CIP |

62.3 |

67.8 |

72.4 - 77.9 |

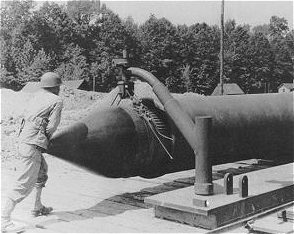

Q. What was the largest gun in history?

A. The largest gun ever used in combat

is generally accepted to be

the German "Gustav Gun" (and its sister canon "Dora") built in 1941 by the Krupp company. It had an 80 cm bore

(31.5") and fired either a 10,500 lb HE projectile (which made a crater 30 feet wide

and 30 feet deep) or a 16,500 lb concrete piercing projectile (which would penetrate 264

feet(!) of reinforced concrete). The typical powder charge was about 3000 lb of powder.

The range was between 23 and 29 miles and the muzzle velocity was about 2700 f/s. The gun

weighed 1344 tons and had a crew of 500 men. It was used by the German's during the siege at

Sevestapol in April 1942.

![The Gustav Gun [36k jpg]](gustav.jpg)

One round from Gustav destroyed a Russian ammunition dump 100 feet below Severnaya

Bay and covered by 10 meters of concrete, and a near miss capsized a large ship in the harbor.

Gustav fired 300 rounds during the siege wearing out the original barrel in the process.

A second gun, called "Dora" was set up west of Stalingrad in mid-August.

It was hurriedly withdrawn in September to avoid capture and never saw action. Gustav next appeared outside Warsaw, Poland,

where it fired 30 rounds into Warsaw Ghetto during the 1944 uprising.

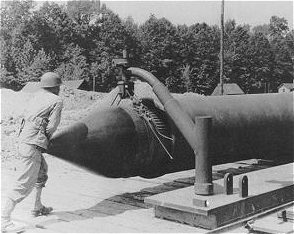

Late in WW II the US developed a "mortar" called the Little

David which fired a 36 inch (92.5 cm), 3700 pound shell containing about 3/4

ton of explosives about 10,000 yards. Intended for use during the invasion of

the Japanese homeland, it was never fired in combat. It required 2 tractors to

transport the base and the tube separately.

|

|

|

| Mortar in place |

36"

projectile |

Loading

projectile |

Q. Can you recommend any "homemade" gun cleaning or lubricating solutions?

A. Due to the amount of information

this section has been moved to its own page. Click

here to visit it.

Please email comments to Fr. Frog by clicking

here.

| Back to Q&A Index | Ballistics Main

Page |

| Back to Fr. Frog's Home Page |

Disclaimer

As far as I know all the information presented above is

correct and I have attempted to ensure that it is. However, I am not responsible for any

errors, omissions, or damages resulting from the use or misuse of this information, nor

for your doing something stupid with it. (Don't you hate these disclaimers? So do I, but

there are people out there who refuse to be responsible for their own actions and who will

sue anybody to make a buck.)

Updated 2020-02-29

![The Gustav Gun [36k jpg]](gustav.jpg)