|

|

...but not canon proof. That must have hurt! |

This section contains brief discussions of various ballistics and shooting related topics as requested by correspondents. If you have a question you have been trying to find an answer to (keep 'em ballistics and shooting related--see your minister for the mysteries of life) email me by clicking here and I'll do my best to find the answer for you and if it is of general interest, publish it here. If you can contribute additional input to one of the answers I'd would appreciate hearing from you too.

Check back frequently as new topics are always being added.

On this page:

How do you measure the Brinell hardness

of lead alloys?

Are there any ways to improve the hardness of my cast

bullets?

What temperature do you recommend for casting bullets?

Is there any way to determine the bullet hardness needed?

I have several lots of different alloys. How can I mix them

to obtain a desired hardness?

Do cast bullets harden or soften with age?

Besides

the shape of the grains what is the difference between ball and extruded (stick)

powders?

How accurate are the

velocity and performance specifications given in manufacturers ammunition

brochures?

How effective would the armor worn by

knights be against gunfire?

What color front sight insert is best?

What kind of bullets are best in the brush?

What would happen to the point of impact if a rifle was

held upside down?

How is group size measured?

Who invented the first jacketed bullet?

What were "guard cartridges?"

Q. How do you measure the Brinell hardness of lead alloys?

A. The measuring of the Brinell hardness of lead alloys is easy to do if you have access to some pure lead and a 1/2" to 1" steel bearing ball. You need to use pure commercial pig lead and not scrap or reclaimed lead of unknown composition. Cast an ingot of the pure lead and an ingot of the alloy in question. Place the steel ball between the two ingots and compress them in a vice until the indent in the lead is about 1/4 the diameter of the ball. (The test sample should be at least 4 times as thick as the diameter of the indent expected.) Remove the ingots from the vice and very carefully, using a micrometer or an optical measuring loupe ("pocket comparator"), measure the diameter of each impression.

Approximate Brinell Hardness = 5 * (diameter of indent in lead / diameter of indent in alloy)2

I recently stumbled upon a nifty device produced by LEE Precision that also allows you to measure alloy hardness. They offer a "Hardness Tester," product # 90924 for $58. See http://www.leeprecision.com/ for ordering and additional information is available at http://www.realguns.com/archives/118.htm. It consists of a spring loaded hardened point that you mount in a reloading press, a cradle for the sample that mounts on the ram, and a 20X measuring microscope. It comes with a conversion chart that relates the BHN of the alloy to alloy strength and maximum useable pressures. The chart stops at BHN 8.0. Since the relationships in the Lee chart are purely mathematical the complete the chart down to BHN 5.0 (pure lead) is given below.

|

Lee Hardness Tester Chart |

|||||||||||

|

Imprint |

Bhn |

Strength |

Working Pressure |

Imprint |

Bhn |

Strength |

Working Pressure |

Imprint |

Bhn |

Strength |

Working Pressure |

|

0.038 |

36.6 |

52,045 |

46,900 |

0.059 |

14.9 |

21,188 |

19,021 |

0.080 |

7.8 |

11,092 |

9,983 |

|

0.039 |

34.8 |

49,486 |

44,489 |

0.060 |

14.3 |

20,335 |

18,367 |

0.081 |

7.6 |

10,807 |

9,726 |

|

0.040 |

33.0 |

46,926 |

42,256 |

0.061 |

13.9 |

19,766 |

17,745 |

0.082 |

7.4 |

10,523 |

9,471 |

|

0.041 |

31.4 |

44,651 |

40,185 |

0.062 |

13.4 |

19,055 |

17,152 |

0.083 |

7.2 |

10,238 |

9,214 |

|

0.042 |

29.9 |

42,518 |

38,260 |

0.063 |

13.0 |

18,486 |

16,588 |

0.084 |

7.1 |

10,096 |

9,086 |

|

0.043 |

28.5 |

40,527 |

36,461 |

0.064 |

12.5 |

17,775 |

16,050 |

0.085 |

6.9 |

9,812 |

8,831 |

|

0.044 |

27.2 |

38,678 |

34,796 |

0.065 |

12.1 |

17,206 |

15,536 |

0.086 |

6.8 |

9,670 |

8,703 |

|

0.045 |

26.0 |

36,972 |

33,234 |

0.066 |

11.8 |

16,780 |

15,046 |

0.087 |

6.6 |

9,385 |

8,444 |

|

0.046 |

24.8 |

35,266 |

31,713 |

0.067 |

11.4 |

16,211 |

14,511 |

0.088 |

6.4 |

9,101 |

8,191 |

|

0.047 |

23.8 |

33,844 |

30,405 |

0.068 |

11.0 |

15,642 |

14,128 |

0.089 |

6.3 |

8,959 |

8,063 |

|

0.048 |

22.7 |

32,279 |

29,120 |

0.069 |

10.7 |

15,215 |

13,699 |

0.090 |

6.2 |

8,816 |

7934 |

|

0.049 |

21.8 |

31,000 |

27,914 |

0.070 |

10.4 |

14,789 |

13,288 |

0.091 |

6.0 |

8,532 |

7,679 |

|

0.050 |

20.9 |

29,720 |

26,719 |

0.071 |

10.1 |

14,362 |

12,895 |

0.092 |

5.9 |

8,390 |

7,751 |

|

0.051 |

20.1 |

28,582 |

25,710 |

0.072 |

9.8 |

13,936 |

12,517 |

0.093 |

5.8 |

8,248 |

7,423 |

|

0.052 |

19.3 |

27,445 |

24,703 |

0.073 |

9.5 |

13,509 |

12,155 |

0.094 |

5.7 |

8,105 |

7,295 |

|

0.053 |

18.6 |

26,449 |

23,751 |

0.074 |

9.2 |

13,082 |

11,801 |

0.095 |

5.5 |

7,821 |

7,039 |

|

0.054 |

17.9 |

25,454 |

22,852 |

0.075 |

9.0 |

12,798 |

11,473 |

0.096 |

5.4 |

7,679 |

6,911 |

|

0.055 |

17.2 |

24,458 |

22,002 |

0.076 |

8.7 |

12,371 |

11,152 |

0.097 |

5.3 |

7,537 |

6,783 |

|

0.056 |

16.6 |

23,605 |

21,196 |

0.077 |

8.5 |

12,087 |

10,844 |

0.098 |

5.2 |

7,394 |

6,654 |

|

0.057 |

16.0 |

22,752 |

20,433 |

0.078 |

8.2 |

11,660 |

10,541 |

0.099 |

5.1 |

7,252 |

6,527 |

|

0.058 |

15.4 |

21,899 |

19,109 |

0.079 |

8.0 |

11,376 |

10,261 |

0.100 |

5.0 |

7,110 |

6,399 |

The "strength" column roughly relates to the maximum pressure that particular hardness bullet is suited for.

This table was originally published on the The Frontier Sixshooter Discussion Board at http://www.sixshootercommunity.com

Q. Are there any ways to improve the hardness of my cast bullets?

A. Yes. There are two fairly easy ways to gain additional hardness, especially if your alloy contains wheel weights and their antimony and arsenic.

The first is to heat treat them after they have cooled in a carefully temperature controlled oven at 475 - 480 degrees F for 2 hours and to then quench them in room temperature water. This requires careful temperature control because most alloys will start to melt at about 486 degrees. The second way is to drop the bullets directly from the hot mold into a tub of room temperature water. (Note: This needs to be done in a manner that will ensure that no water will splash on the hot alloy in the casting pot.)

The table below shows the effects of these treatments on an alloy composed of 5 percent antimony, .5 percent tin, .17 percent arsenic, and 94.3 percent lead, but the results for other common alloys are similar.

| Treatment | Brinell Hardness |

| Air cooled normally | 16 |

| Quenched directly from mold | 28 |

| Heat treated and quenched | 36 |

Q. What temperature do you recommend for casting bullets?

A. To minimize the formation of oxides which produce the dross (scum) on the surface of molten casting alloys ideally the temperature used for casting should be only slightly higher than the melting point of lead (621° F). However, to get good filling out of the mold most casters run about 625° to 675° F. Note that the mold must be up to temperature for the bullet to properly fill out the mold.

Q. Is there any way to determine the bullet hardness needed?

A. See the article on measuring hardness, above. There is a formula that purports to relate Brinell hardness (BHN) to different operating cartridge pressures:

BHN x 1,422 = Pressure needed to "upset" or "obdurate" the bullet properly.or

BHN = ( Cartridge Pressure / 1,422 )

The 1,422 number comes from converting the pressure in Kg/mm2 (which is what the BHN is measured in) to lb/in2 (which is what we use for cartridge pressure). That is: conversion factor = 25.40 (mm/in) x 25.40 (mm/in) x 2.2046 (lb/kg) = 1,422.

There are several sources that say the best accuracy for a plain based lead bullet is when the pressure of the cartridge is 90% to 100% of the strength of the bullet so the final formula would be

BHN = ( Cartridge Pressure * 1.1) / 1,422 or Cartridge Pressure = BHN * 1422 * .9

Veral Smith’s book Jacketed Performance with Cast Bullets and Richard Lee’s Modern Reloading 2nd Ed., cover this relationship great detail. The NRA's Cast Bullets book by Col. E.H. Harrison which is out of print and several of the Lyman casting books allude to this relationship by listing what bullet hardness is necessary for best accuracy at different cartridge velocities. They do not mathematically tie the hardness and pressure together, though, as the first two books do. The above formula seems to hold true up to about 30,000 psi loads.

Q. I have several lots of different alloys. How can I mix them to obtain a desired hardness?

A. If the hardness of the various alloys are known (see the above Q&A on measuring Brinell hardness) it is relatively easy to come up with a mix. As an example we'll assume that we have 3 alloys on hand with measured BHNs of 12.5, 17.5, and 20. We'd like to approximate Lyman #2 (BHN=15).

| Weight | BHN | Mix # | ||

| 1 | x | 20 | = | 20 |

| 3.5 | x | 17.5 | = | 61 |

| 4 | x | 12.5 | = | 50 |

| 8.5 | 131 |

By modifying the amount of each alloy used in a mix we can come up with a desired hardness by dividing the sum of the "mix numbers" by the total weight of the materials used. In this example:

131 / 8.5 = 15.4

Note that when mixing alloys that you don't need to have more than about 4 percent tin in a lead/tin/antimony mix as the primary effect of the tin is to improve material flow for a better filled out mold and most of the hardening comes from the antimony. When casting with wheel weights I usually add one 1 pound bar of 60/40 solder (about .6 pounds of tin) to 20 pounds of wheel weights to bring the tin content up a bit.

Q. Do cast bullets harden or soften with age?

A. It depends on the composition of the alloy. Tin-lead alloys gradually lose their hardness over about 20 days and then stabilize. A 1:10 alloy loses about 4 BHN and a 1:16 alloy will lose about 2 BHN. Alloys containing antimony (wheel weights, linotype, and various mixes) gain about 6 BHN over a 20 day period and then stabilize. Heat treated or cold quenched antimonial alloys will drop a bit from their peak hardness by about 2 - 3 BHN in a couple of days and then level out. After about 2 - 3 months they exhibit a slow decline in hardness but since the heat treatment or quenching can almost double the original hardness it is of little concern.

Q. Besides the shape of the grains what is the difference between ball and extruded (stick) powders?

A. Ball powders were specifically designed to flow and measure evenly from production loading equipment and they measure very uniformly in automated powder dispensing machines. Both ball and extruded powders are essentially made of the same components, nitrocellulose or nitrocellulose and nitroglycerine. Extruded powders are literally extruded and cut to length like spaghetti or macaroni during manufacture while ball powders are rolled into roughly spherical shape. Extruded powders rely primarily on grain size/surface area to control the burn rate while ball powders rely on the effects of a deterrent coating and generally need a "hot" or "magnum" primer to function well.

Ball powders work well under normal conditions and generally give slightly slower throat erosion than extruded powders. They also have good pressure vs. velocity ratios. However, under extremes of temperature they can exhibit undesirable pressure effects, including inverse pressure/temperature relationships (higher pressures at lower temperatures).

In addition, under certain circumstances, primarily when using light bullets, the deterrent coating on ball powder can compromised resulting in unusual burning characteristics and pressure fluctuations that can be dramatic. This effect has been documented but is not fully understood. It is believed to be related to the lower resistance of the lighter bullet and the fact that the grains may be scattered down the bore and ignited simultaneously rather than via the usual ignition process. Either type of powder will produce excellent results in normal loads but I would avoid the use of ball powder in light bulleted loads such as 40 - 45 gr .223 and 110-130 gr .30 caliber loads.

There have recently come to light some non-canister (non-commercial) uncoated ball powders that burn like extruded powders via specific grain shapes that are finding use in some ammunition, but information of them is sketchy.

Q. How accurate are the velocity and performance specifications given in manufacturers ammunition brochures?

A. SAAMI specifications call for the actual velocity to be ± 90 f/s from the published data when fired in a specifically dimensioned test barrel of a specified length. The results when fired in a commercial production barrel can deviate significantly depending on the internal dimensions and wear. I have seen differences of almost 200 f/s from a production barrel of the same length as the test barrel

The published trajectories have been commonly based on an estimated ballistic coefficient derived from visual comparison and based upon the old Ingalls tables or the common G1 model which does not accurately model the flight of modern pointed and boat tail bullets. At any range past 200 - 300 yards they are probably way off and should not be relied upon. Some manufacturers have finally realized that their data was way off and have begun publishing more accurate data based upon actual firing data, but you can't be sure. If you are serious about hitting you need to chronograph and calculate your own tables.

Q. How effective would the metal armor worn in the 16th and 17th centuries be against gunfire?

A. Plate armor of that period was proofed using a 1 oz lead ball fired from a musket with a charge of black powder sufficient to cover the ball placed on a flat surface, or "half proofed" using one-half of this powder charge. A test was done in the early 60s by NRA technical staff using a breast plate, circa 1622-1660, that was made out of plate approximately .135" thick. Firing tests were conducted at 24 feet and yielded the following results.

| Firearm | Depth of Dent | Velocity (f/s) | KE (ft/lb) |

| Original proof test | deep dent | unknown | unknown |

| .710" 546 gr Musket* | very deep dent | 870 | 917 |

| 40 gr .22RF LR standard velocity | no dent | 1079 | 103 |

| 40 gr .22RF LR HS | shallow dent | 1350 | 163 |

| 50 gr FMJ .25ACP | very shallow dent | 839 | 78 |

| 95 gr FMJ .380ACP | shallow dent | 939 | 186 |

| 158 gr .38Spl LRN-HV | shallow dent | 867 | 264 |

| 246 gr LRN .44 Spl | shallow dent | 718 | 282 |

| 230 gr FMJ .45ACP | shallow dent | 766 | 300 |

| 158 gr LSWC .357 Mag | deep dent | 1316 | 656 |

| 124 gr FMJ 9 x 19 mm | very deep dent | 1189 | 389 |

| 240 gr LSWC .44 mag | penetrated | 1667 | 1481 |

| * 546 gr lead ball and 140 gr Fg black powder | |||

|

|

...but not canon proof. That must have hurt! |

Q. What color front sight insert is best?

A. Most people seem to like day-glow red or red-orange inserts but that color is not one that the eye is most sensitive to, that color being a yellow-green.

|

While the yellow-green is the most visible to the eye it may not be as suitable under field conditions needing a color contrast. Try several colors and see what works best for you under your conditions.

Eye sensitivity graph courtesy of http://www.amastro.org/at/ot/othcs.html

Q. What kind of bullets are best in the brush?

A. That is a question that has been investigate and batted around for some time and the results of tests seem to vary with the exact test used. Conventional wisdom says that big, heavy, slow bullets are best yet many tests show different results. The most thorough test I've seen, produced the following information.

Maximum deflections at 50 yards in this test ranged from 3.5" to 51" with the .223 55 gr M193 Ball and 7 mm Mag 150 gr giving the least deflection and the 12 ga 1 oz slug and 140 gr .264 Win Mag giving the most deflection, among common cartridges. The venerable 405 gr .45-70 gave 28.5" of deflection. Most noticeable was the affect that bullet construction had on deflection characteristics in each caliber.

What can be learned from this? Simply don't shoot through intervening braches or limbs if at all possible, as results vary greatly and the chances of hitting your target are greatly reduced. Stalk and get closer or to a position with a clear field of fire.

Maybe Rule 4 should be amended to read, "Be sure of your target and what is behind and in front of it.

Q. What would happen to the point of impact if a rifle was held upside down?

A. As an example lets assume we're using a .30-30 170 gr load and in the normal firing position the rifle is sighted in to be zeroed at 150 yards. This bullet drops 11 inches from the bore line at 150 yards (not accounting for any sight height). When the rifle is held and sighted upside down the bore will point at a spot about 11 inches under the point of aim and the bullet will still drop its 11 inches at that range. This means the bullet will strike about 22 inches below the point of aim.

|

Q. How is group size measured?

A. Group size is the measurement between the centers of the two most widely spaced bullet holes, and not from the outside to outside. Since the center of the hole is often difficult to determine group size can be measured from same edge of the tops, bottoms, or sides of the widest spaced holes. When groups are "one-holers" the group size can be determined by measuring the widest diameter of the "hole" and then subtracting the diameter of a sample hole made by a single bullet.

|

|

| Measuring widely spaced shots | Measuring "one-holers." |

Q. Who invented the first jacketed bullet?

A. The first jacketed bullets were developed in Europe in the early 1870s. Military rifles of that period fired large diameter soft lead bullets which deformed on striking anything hard. This led to charges and counter charges that all parties in the late 19th century European wars were using explosive bullets to inflict terrible wounds. A LTC Bode of the Prussian Army was probably the first to experiment with bullets covered in a thin jacket of copper, around 1874, almost 20 years before they were used in the United States.

Q. What were "guard cartridges?"

A. "Guard cartridges" were lower powered cartridges issued to to prison guards and riot troops. They were fairly common from the late 1890s through most of WWII. Typically they were loaded with round balls, lead bullets, or standard service bullets over a reduced powder charge. Velocities were typically about 1000-to 1200 f/s.

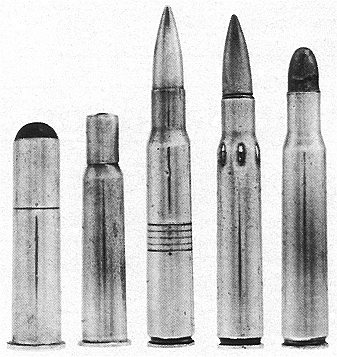

|

| Guard cartridges (L-R): .45-70 single ball, .30-40 Multiball, two variations of .30-06 Jacketed service bullet, M1911 .30-06 gallery load. |

Please email comments to Fr. Frog by clicking here.

| Back to Q&A Index | Ballistics Main Page |

| Back to Fr. Frog's Home Page |

Disclaimer

As far as I know all the information presented above is correct and I have attempted to ensure that it is. However, I am not responsible for any errors, omissions, or damages resulting from the use or misuse of this information, nor for you doing something stupid with it. (Don't you hate these disclaimers? So do I, but there are people out there who refuse to be responsible for their own actions and who will sue anybody to make a buck.)

Updated 2015-06-20